AC Distress Decision Points

Disintegration

Disintegration in a flexible pavement is typically caused by climate, insufficient compaction of the surface, insufficient asphalt binder in the mix, loss of adhesion between the asphalt coating and aggregate particles, or severe overheating of the mix. The following types of disintegration commonly occur.

Types:

Weathering

Weathering is the wearing away of the asphalt binder and fine aggregate matrix from the pavement surface. The asphalt surface begins to show signs of aging which may be accelerated by climatic conditions. Loss of fine aggregate matrix is noticeable and may be accompanied by fading of the asphalt pavement color.

Raveling

Raveling is the wearing away of the pavement surface caused by the dislodging of aggregate particles. This distress may indicate that the asphalt binder has aged and hardened significantly. As the raveling continues, larger pieces break free, and the pavement takes on a rough and jagged appearance which can produce a significant source for FOD.

Cracking

Cracks in flexible pavements are caused by deflection of the surface over an unstable foundation, shrinkage of the surface, thermal expansion and contraction of the surface, poorly constructed lane joints, or reflection cracking. The following types of cracks commonly occur in flexible pavements.

Types:

Longitudinal Cracking

Longitudinal cracks may result from shrinkage or contraction of the HMA surface. Shrinkage of the surface material is caused by oxidation and age hardening of the asphalt material. Contraction is caused by thermal fluctuations. Poorly constructed paving lane joints may accelerate the development of longitudinal joint cracks. This type of cracking is not load associated.

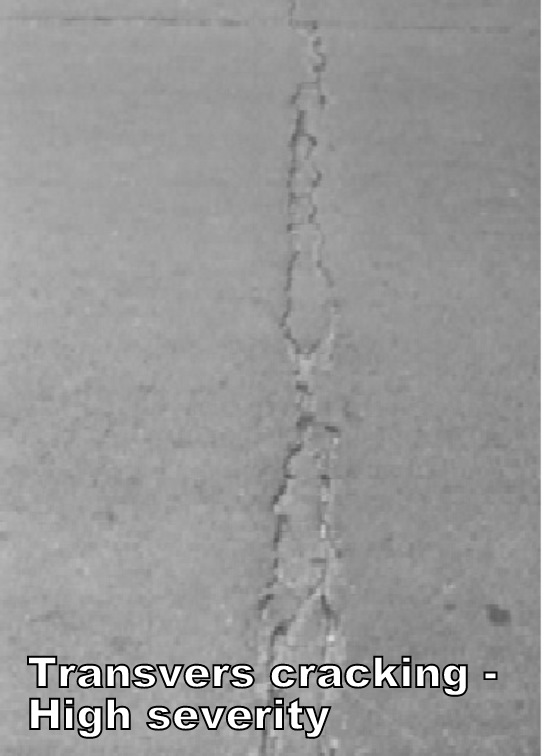

Transverse Cracks

Transverse cracks may result from shrinkage or contraction of the HMA surface. Shrinkage of the surface material is caused by oxidation and age hardening of the asphalt material. Contraction is caused by thermal fluctuations.

Block Cracking

Block cracks are interconnected cracks that divide the pavement into approximately rectangular pieces. The blocks may range in size from approximately 1 foot by 1 foot (0.3 m by 0.3 m) to 10 feet by 10 feet (3 m by 3 m). Block cracking is caused mainly by contraction of the asphalt and daily temperature cycling that results in daily stress/strain cycling. It is not load associated. The occurrence of block cracking usually indicates that the asphalt has hardened significantly. Block cracking normally occurs over a large portion of pavement area, but sometimes will occur only in non-traffic areas. Block cracking differs from alligator cracking.

Reflection Cracking

Vertical or horizontal movement in the pavement beneath an overlay cause this type of distress. This movement may be due to expansion and contraction caused by temperature and moisture changes or traffic loads. The cracks in HMA overlays reflect the crack pattern or joint pattern in the underlying pavement. They occur most frequently in HMA overlays on PCC pavements. However, they may also occur on overlays of HMA pavements when cracks or joints in the old pavement have not been properly repaired.

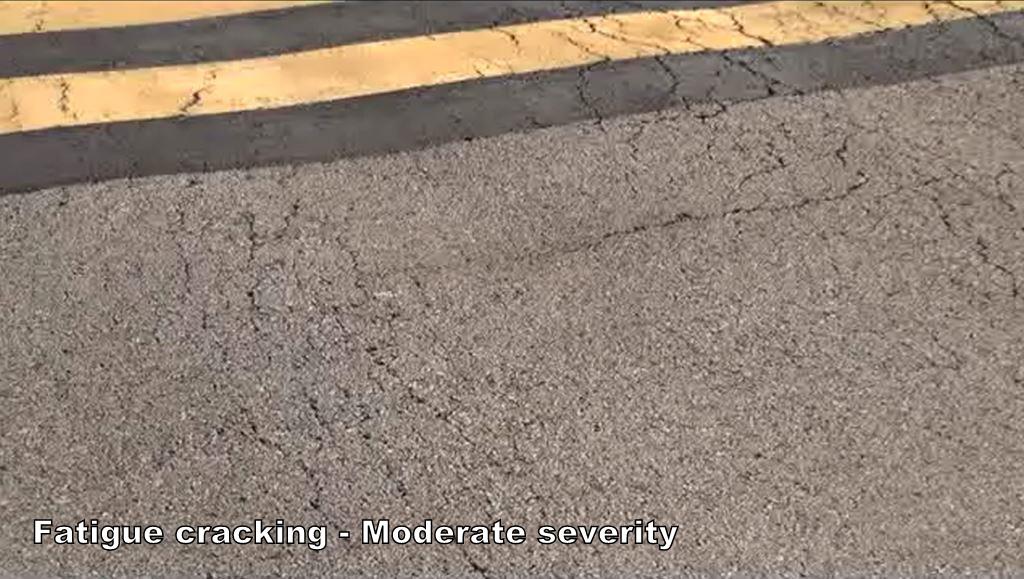

Alligator (Fatigue) Cracking

Alligator (fatigue) cracking is a series of interconnecting cracks caused by fatigue failure of the HMA surface under repeated traffic loading. The cracking begins at the bottom of the HMA surface (or stabilized base) where tensile stress and strain are highest under a wheel load. The cracks propagate to the surface initially as a series of parallel cracks. After repeated traffic loading or excessive deflection of the HMA surface over a weakened or under-designed foundation or interlayer, the cracks connect, forming many sided sharp angled pieces that develop a pattern resembling chicken wire or alligator skin. The pieces are less than 2 feet (0.6 m) on the longest side.

Roughness

Need content.